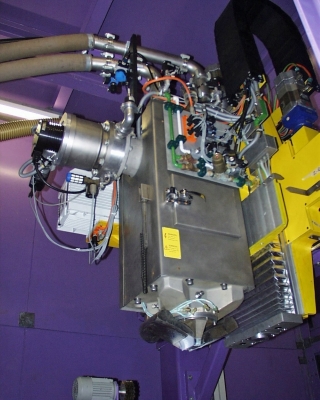

EBOPULS Electron Beam Drilling System

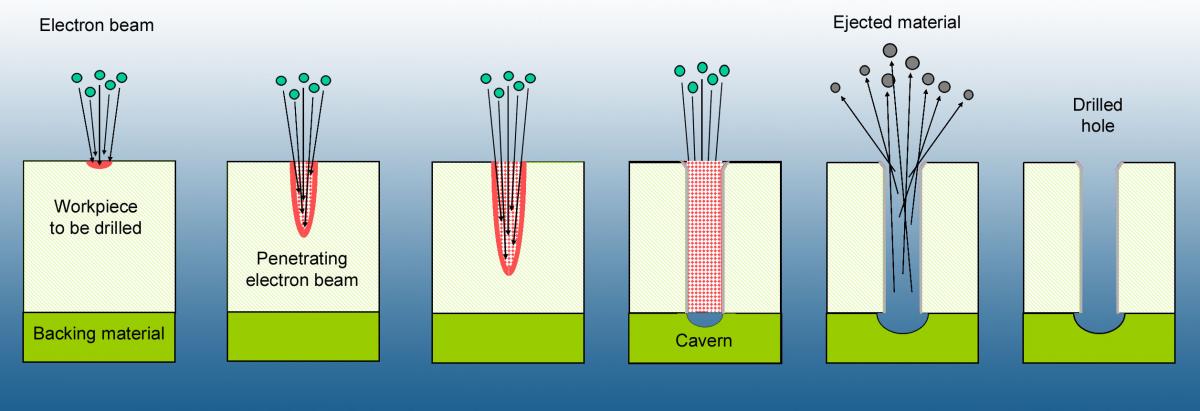

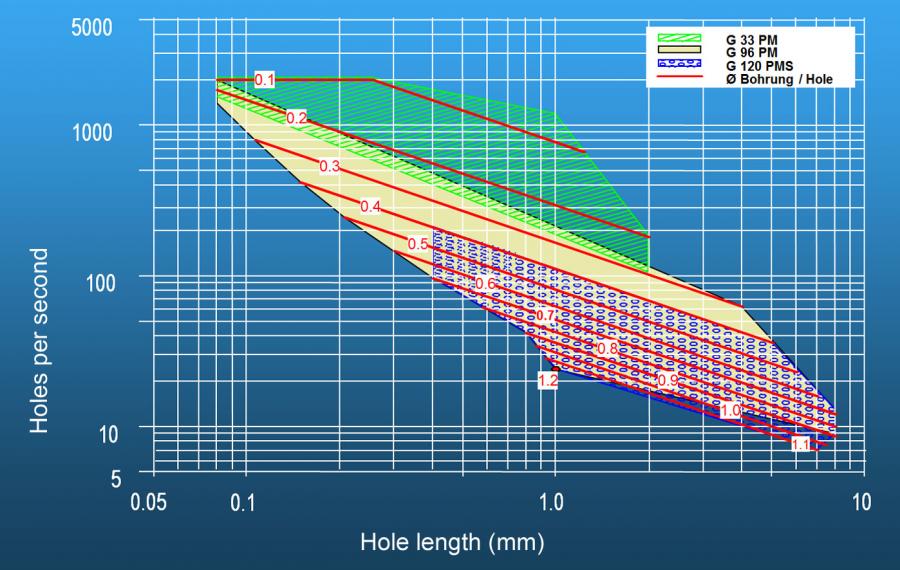

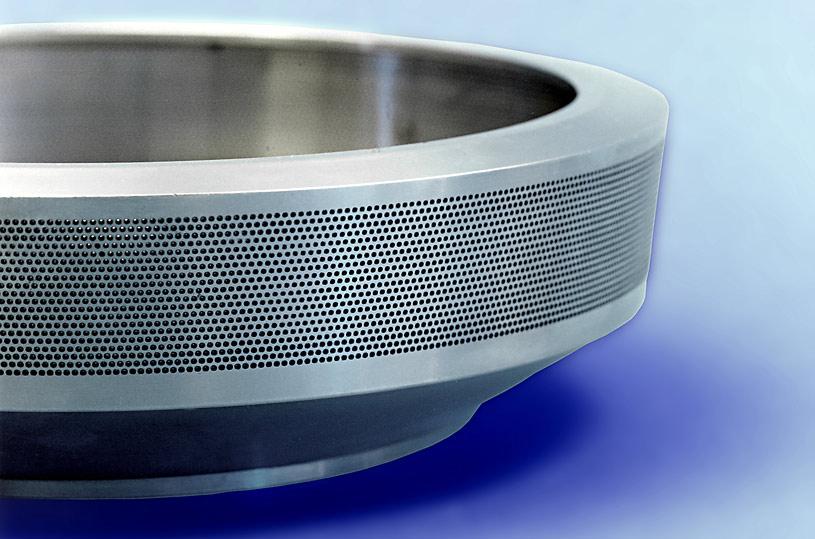

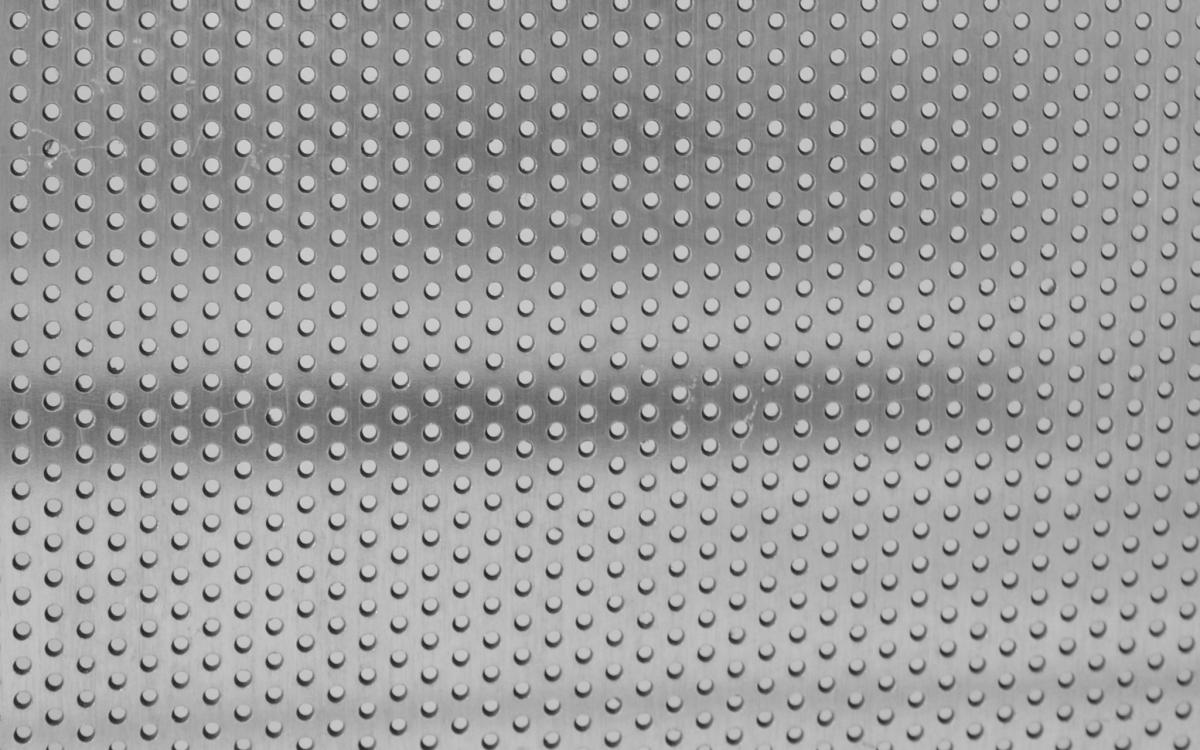

A densely focused, high kinetic energy electron beam and high speed control of the electron beam enables fast and accurate through-hole drilling in workpieces, especially ones requiring tens of thousands or even millions of holes. Nearly all metals and certain ceramics can be drilled using an electron beam- independent of hardness, reflectivity, alloy type or high thermal conductivity.

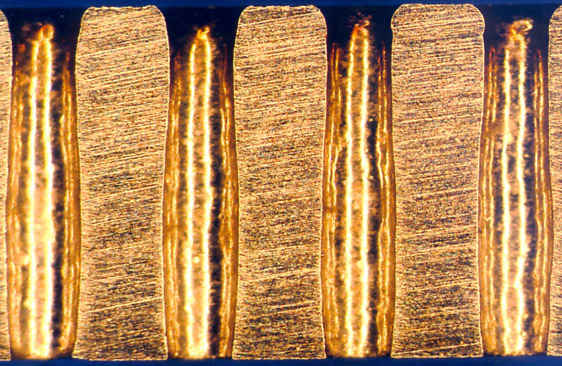

The characteristics of Electron Beam (EB) drilling make what we call "drilling on the fly" possible. The inertia free control of an electron beam allows the drilling of holes with a focused beam that moves with the same speed as the part surface. This unique feature combined with a beam shaping device (stigmator) drills round holes while the part is moving. There is only one beam pulse needed to drill a hole, resulting in very high production rates and very smooth hole surfaces.

The Steigerwald Strahltechnik EBOPULS electron beam drilling system is part of the Global Beam Technologies Group product line.

Electron beam welds are known as very high quality welds with superior repeatability- this is also true for the non-vacuum process. All controls of the welding processes, up to the closed loop beam current controller, are integrated in the non-vacuum system.

Electron beam welds are known as very high quality welds with superior repeatability- this is also true for the non-vacuum process. All controls of the welding processes, up to the closed loop beam current controller, are integrated in the non-vacuum system.